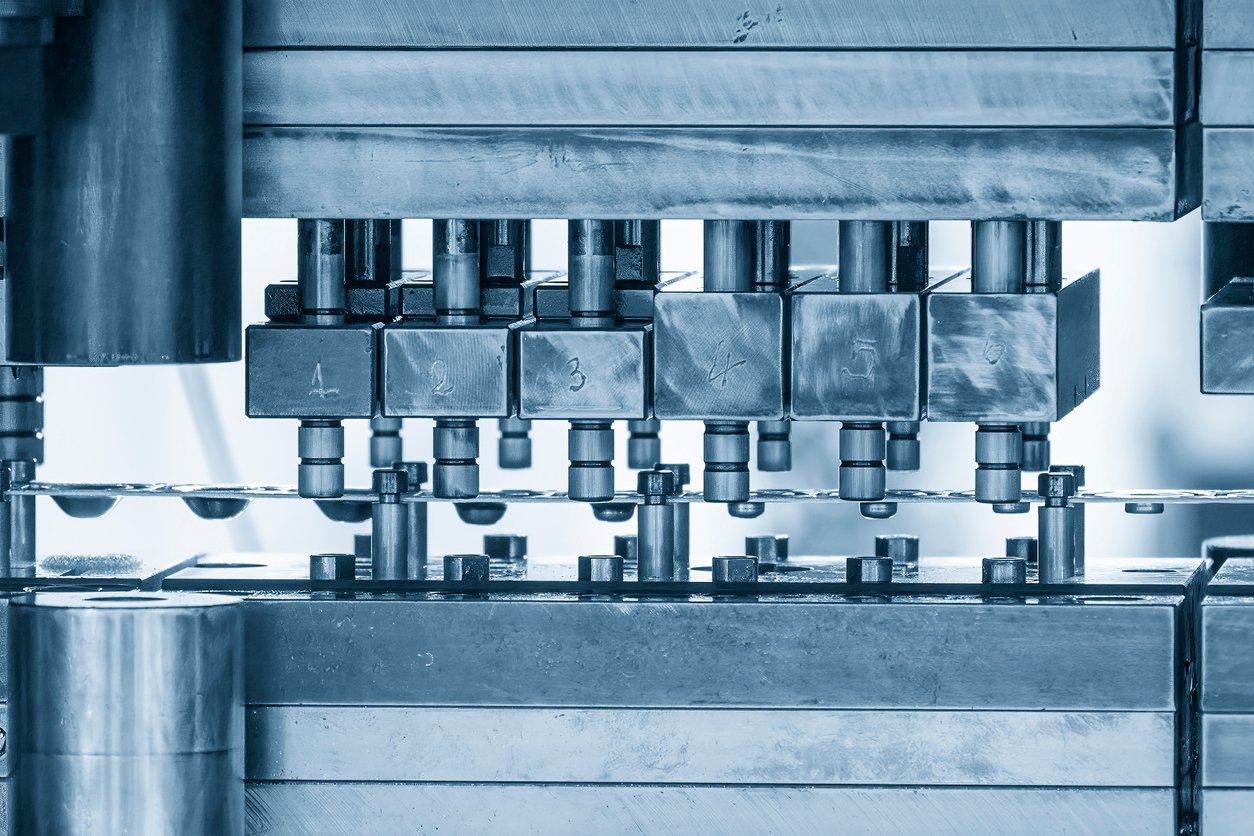

Die Steel Material Choices That Shape Progressive Stamping

Selecting the right material is important in progressive die stamping. It directly affects components' strength, durability, and performance, ensuring they meet specific industry standards.

What’s the secret to choosing the right die steel material? It’s in the properties.

While tooling and die design are important, the characteristics of the materials—like strength, corrosion resistance, and conductivity—enable the production of high-quality stamped parts. With so many material options available, in this article, we will break down the following:

- Key considerations for material selection

- Influence of part complexity on material selection

- Common materials used in progressive die stamping

- Pricing and cost considerations

Key Considerations for Material Selection

Understanding what influences die steel material and how complex the part is is key to designing efficient and durable progressive dies. These considerations can impact die performance, production costs, maintenance, and component quality.

Factors Influencing Material Choice

There are five key factors to consider when choosing stamping die material:

- Strength and durability requirements

- Formability and machinability considerations

- Corrosion resistance needs

- Cost-effectiveness and budget constraints

- Environmental factors

1. Strength and Durability Requirements

The choice of material should align with the final product's specific strength and durability demands.

For instance, high-strength steels or alloys may be necessary to withstand operational stresses, ensuring the tool’s long-term reliability and that components meet performance standards for their intended applications.

2. Formability and Machinability Considerations

Choosing materials with excellent formability and machinability, such as aluminum or soft steel, is essential for efficient manufacturing.

They simplify shaping and cutting, helping to reduce time and labor costs and optimize production.

3. Corrosion Resistance Needs

It is important to select materials with high corrosion resistance in applications where exposure to corrosive elements or environments is likely.

Stainless steel or coated metals can prevent degradation over time, ensuring the parts maintain their integrity and functionality even in harsh conditions. This is especially important for parts submerged in water, such as those used in the nuclear industry, or for components in construction projects.

You can ensure long-term durability and performance by choosing materials designed to withstand these environments.

4. Cost-effectiveness and Budget Constraints

Material selection must balance performance with financial considerations. The die steel material should meet the required properties and performance standards within cost constraints.

This requires carefully evaluating the cost-benefit ratio of each material to ensure quality without overspending.

5. Environmental Factors (e.g., Sustainable Materials)

With sustainability becoming a significant consideration, choosing environmentally friendly materials reduces the ecological impact of manufacturing processes.

This includes selecting recyclable or biodegradable materials, supporting efforts to minimize waste and promoting eco-friendly manufacturing practices.

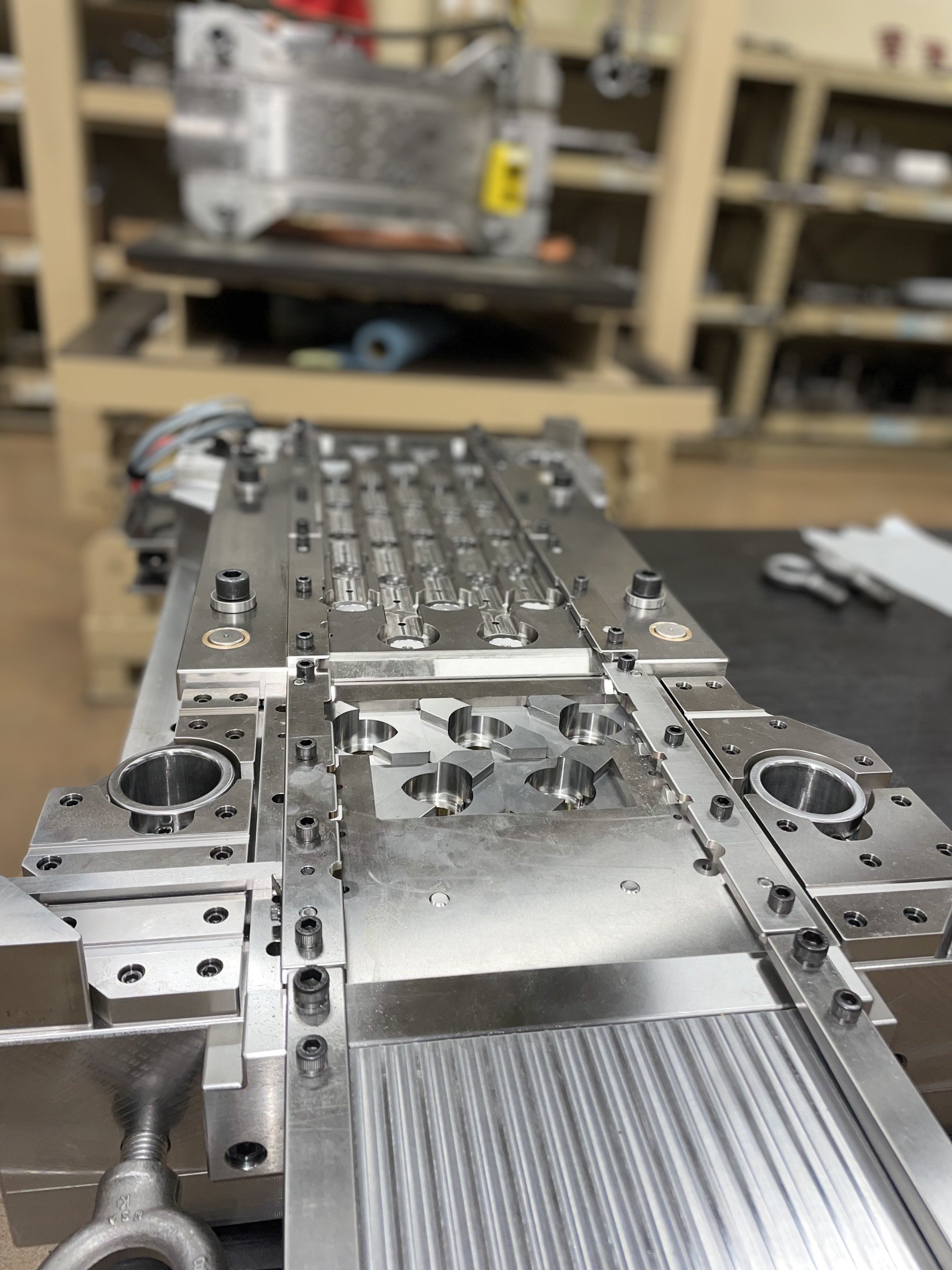

Influence of Part Complexity on Material Selection

There are two key factors to consider when determining how part complexity affects material selection are important to ensure that each component produced meets design specifications while optimizing efficiency:

1. Need for Tight Tolerances and Intricate Designs

Material selection becomes important when producing components with tight tolerances and intricate designs. Precision machining and forming require materials that remain stable throughout manufacturing.

Materials prone to deformation or inconsistencies can lead to deviations from specifications, compromising quality. Choosing materials that withstand intense production processes ensures components meet exact standards – especially vital in aerospace, automotive, and medical device manufacturing, where even minor errors have significant consequences.

2. Impacts of Material Properties on Tooling and Metal Stamping Dies

The properties of the materials used in production, such as hardness and abrasiveness, determine the wear and tear experienced by progressive die stamping.

More challenging, more abrasive materials tend to cause more wear, reducing the lifespan of these tools. This wear can increase production costs due to frequent replacements or repairs and potential downtime. Manufacturers can improve production efficiency and lower maintenance costs by selecting materials that minimize this wear.

Hardened tool steel, known for its durability and resistance to wear, can significantly extend the operational life of metal stamping dies, improving productivity and ensuring the quality and precision of the manufactured components are maintained over longer production runs.

Carbide and hardened steel are also commonly used because most of the tools we build now feature carbide cutting and forming materials, which offer enhanced strength and wear resistance for high-performance applications.

Common Materials Used in Progressive Die Stamping

Understanding the common materials used in progressive die stamping lays the foundation for their practical applications across various industries. Each material's unique properties, such as strength, formability, and corrosion resistance, determine its suitability for specific applications.

Below is an overview of how these materials are leveraged across different sectors, highlighting their role in manufacturing processes and their benefits to their application:

|

Material |

Characteristics/Benefits |

Applications/Use Cases |

|

Stainless Steel |

Exceptional corrosion resistance and significant strength, suitable for environments exposed to moisture or chemicals. Durable and hygienic, it’s widely used across various industries. |

Extensively applied in manufacturing medical devices and food-processing equipment, where maintaining sterility and longevity is crucial. |

|

Aluminum Alloys |

Lightweight yet strong, with excellent corrosion resistance. Their low weight contributes to fuel efficiency in transportation-related applications. |

Favored in the aerospace industry for components that require strength without significant weight and in consumer electronics for design flexibility. |

|

Copper Alloys (e.g., Brass) |

Good electrical and thermal conductivity, making them indispensable in industries requiring efficient energy transfer or heat dissipation. |

Commonly used for producing electrical components and connectors, where conductive properties and ease of fabrication are essential. |

|

Specialty Metals |

Can withstand high stress or temperatures, making them suitable for advanced engineering applications. They also have high strength-to-weight ratios and thermal resistance. |

Used in aerospace, military, and industrial applications where durability and thermal resistance are critical. |

Want to further your knowledge to achieve higher quality?

Check out Understanding Quality Assurance in Progressive Metal Stamping

Pricing and Cost Considerations for Material Selection

Understanding the cost variations among different metals is helpful when selecting materials for progressive die applications and budgeting for a project.

Material Cost Variations

Understanding material cost variations is essential because they directly impact manufacturing projects' overall budget and feasibility.

Manufacturers can make informed decisions that balance performance with economic constraints by carefully weighing the trade-offs between cost and material properties of the following materials:

- Aluminum: Known for its lightweight properties and corrosion resistance, aluminum tends to be more expensive. It’s preferred for specialized applications where these attributes are crucial.

- Steel: A cost-effective option known for its strength and durability, steel is ideal for applications without critical weight.

- Lower-grade steels: These steels are less costly due to lower performance characteristics. They suit less demanding applications but may underperform in extreme conditions, affecting quality and longevity.

- Brass and stainless steel (alloys): With alloying elements that enhance characteristics like strength or corrosion resistance, these materials offer valuable benefits that come at a higher cost.

Cost vs. Performance Trade-offs

Balancing material cost with performance needs is a key consideration in material selection. While opting for superior-quality materials may increase production costs, understanding the cost vs. the performance tradeoff can lead to significant long-term savings through reduced maintenance and longer product life spans. This involves assessing the benefits of higher-quality materials against budget constraints.

Effective scrap reduction and material use directly impact overall progressive die design. Efficient material use saves resources and minimizes waste, decreasing production unit costs. This efficiency can be achieved by selecting materials that allow precise cutting and shaping, reducing waste through optimal nesting and machining strategies.

Making informed choices in material selection considering cost and performance can help create a sustainable and financially viable manufacturing process.

Steel the Spotlight: Choosing the Right Die Materials

Choosing the right material for progressive die stamping ensures the final component's strength and longevity and the production process's efficiency.

With the right material properties and thoughtful engineering, high-quality, precision-stamped parts that meet the most stringent industry standards are possible. Advanced materials offer unique advantages in demanding applications where standard options might fall short.

Ready to Stamp Out the Competition? Explore More Material Tips and Techniques!

Now that you understand the key factors start selecting materials to improve stamping projects! Discover more insights on material selection and stamping techniques by starting your next project with us.

You May Also Like

These Related Stories

The Metal Stamping Process from Start to Finish

Progressive Die Stamping: An Overview

%201.png?width=146&height=103&name=Slice%203%20(72)%201.png)