The Power 5 Benefits of Outsourcing for Progressive Die Stamping

You’re already falling behind if you’re not considering outsourcing for your progressive die stamping needs.

After all, manufacturing is evolving rapidly, and companies that embrace strategic outsourcing gain a competitive edge.

If your competitors are optimizing costs and improving efficiency through outsourcing, shouldn’t you be aware of how they’re doing it?

If you can capitalize on their gaps, shouldn’t you seize that opportunity?

When shaping your manufacturing strategy, evaluate the potential benefits of outsourcing. It’s a way to streamline production, reduce lead times, and gain access to specialized expertise while focusing on your core business.

This blog will discuss the four core benefits of outsourcing progressive die stamping.

Benefits of Outsourcing Progressive Die Stamping

The main benefits of outsourcing progressive die stamping include:

- Cost efficiency

- Enhanced quality and precision

- Increased production capacity and flexibility

- Focus on core competencies

- Custom die design

1. Cost Efficiency

Outsourcing progressive die stamping significantly reduces the capital investments necessary for purchasing and maintaining specialized equipment and technology.

By leveraging the expertise and infrastructure of an American stamping company, organizations avoid substantial costs associated with acquiring high-precision machinery required for in-house production.

This strategic move allows businesses to allocate more space and resources for other high-priority projects, leading to greater efficiency by removing the need to manage complex production processes in-house. When comparing in-house production costs to outsourcing, several factors come into play, such as:

- Labor: This involves costs to a dedicated workforce and ongoing training.

- Maintenance: This entails ongoing maintenance of all machinery, contributing to high labor costs, including ongoing training.

- Operational overhead: This includes utilities, floor space, and administrative costs. It also includes increased maintenance expenses and the budget's unpredictability.

Outsourcing companies can also access products more affordably than if they purchased stamping equipment. This approach allows them to focus and allocate more resources and space to their standard product manufacturing, leading to technological advancements and rapid market adaptation.

Outsourcing progressive die stamping offers a more predictable cost structure, allowing companies to manage budgets more effectively while benefiting from these specialized partners' advanced capabilities.

2. Enhanced Quality and Precision

Outsourcing progressive die stamping also offers cost advantages and ensures superior quality and precision in production. These specialized partners have advanced technologies and equipment that individual businesses may not access, enabling maximized efficiency and accuracy.

This commitment to maintaining high standards is important for industries where precision and reliability are necessary, such as those producing complex electronic devices or automotive parts requiring durability and performance. Businesses partnering with outsourcing progressive die stamping can trust their products' quality while focusing on their core strengths.

3. Increased Production Capacity and Flexibility

Outsourcing progressive die stamping provides significant benefits when dealing with changing demand and high-volume manufacturing without requiring extra in-house capacity expenditures.

Companies that use specialized vendors can swiftly and efficiently increase production to meet client demand without experiencing delays associated with expanding internal operations. This strategy reduces manufacturing lead times and accelerates time to market. With many resources and a large production network, these external partners can easily adjust to volume increases and changing production requirements.

When a business generates only enough work to keep a press 50% busy, outsourcing makes a lot of sense because it allows the machinery costs to be spread across more products over a longer time. This strategic approach optimizes resource utilization and supports the agile production demands of fast-paced markets.

Companies can benefit from the advanced agility of these production lines, which can implement design changes swiftly while maintaining consistency in quality. This flexibility saves time and reduces costs associated with redesigns and retooling, making it a strategic advantage in fast-paced markets. As a result, businesses leveraging outsourced production facilities have a significant competitive edge, allowing them to respond effectively to market shifts while maintaining focus on innovation and market expansion.

4. Focus on Core Competencies

By outsourcing to a progressive stamping manufacturer, companies can devote more resources and attention to their core competencies and innovation. This strategic reallocation allows businesses to focus on areas that generate unique value, such as research and development, marketing, and product design.

When choosing to outsource the progressive die stamping of components, freeing up significant floor space and capital redirects focus toward developing cutting-edge consumer products in your industry. This shift can boost the product innovation pipeline and strengthen the market position.

With more personnel and space dedicated to the core competencies, companies like these can improve their competitive edge by bringing more innovative and refined products to market faster. This strategic outsourcing allows businesses to realign resources towards their strongest areas, ultimately fostering growth and leadership.

5. Custom Die Design

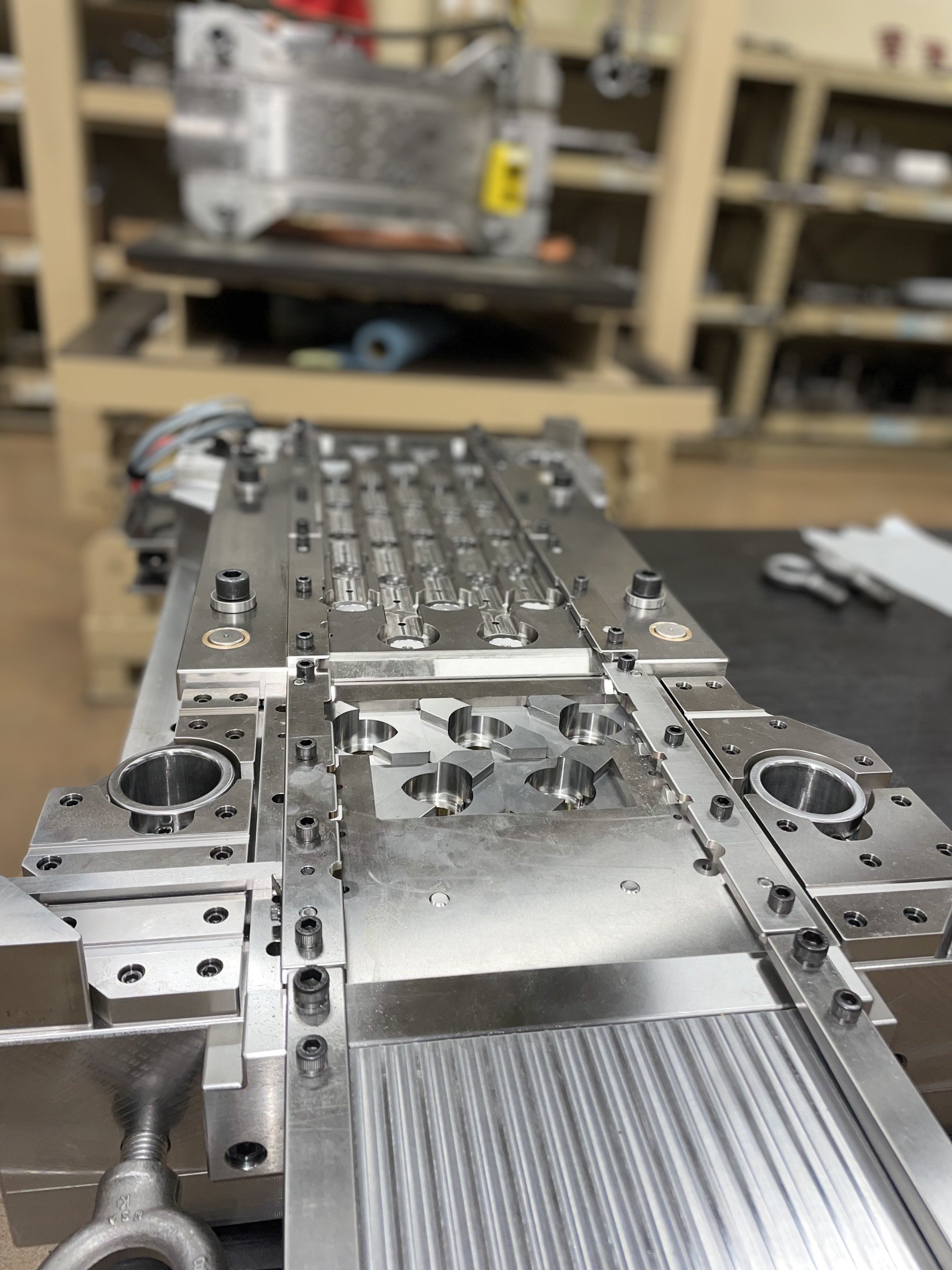

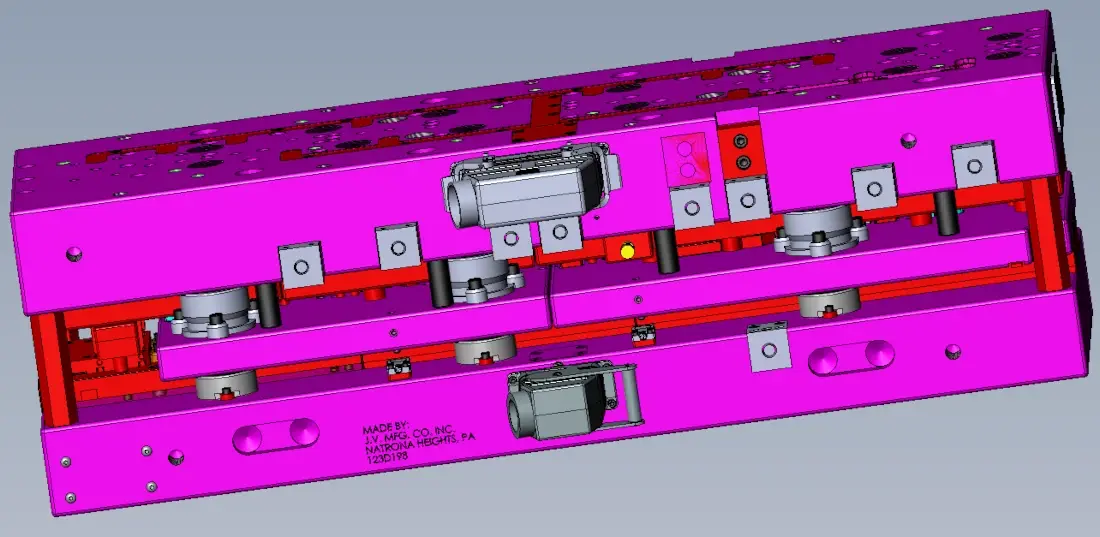

With cutting-edge software and modern machinery, metal stamping companies in the USA can produce die components with exceptional precision, meeting the stringent quality requirements of industries such as automotive and electronics.

An American stamping company can operate a highly skilled workforce trained in the latest die design techniques, ensuring that every product meets high standards. Their expertise allows them to implement strict quality control processes, quickly identifying and addressing design flaws.

Progressive die design partners provide flexible production lines for new designs and modifications. This adaptability is important in dynamic industries where changes happen rapidly, and products evolve frequently. Outsourcing becomes beneficial for companies that need more product volume to fully use a stamping press.

Outsourcing Progressive Die Stamping Is More Than Just Cutting Costs

Outsourcing in progressive die stamping can give your business a competitive advantage, but it’s not just about saving money. While cost reduction and efficiency are important, successful outsourcing goes beyond that. Focus on finding partners who bring specialized expertise, innovation, and flexibility to your operations.

Need Help Evaluating Outsourcing Options?

A well-thought-out outsourcing strategy can optimize your progressive die stamping processes and boost productivity. Our experts can guide you through decision-making and connect you with the right partners for your manufacturing needs.

Contact us today to explore how outsourcing can take your production to the next level.

You May Also Like

These Related Stories

Progressive Die Stamping: An Overview

Die Steel Material Choices That Shape Progressive Stamping

%201.png?width=146&height=103&name=Slice%203%20(72)%201.png)