High Speed Stamping: Processes, Use, Pros, & Cons

Time is valuable in any industry – and in the fast-paced world of manufacturing, high speed stamping shines. This process not only accelerates production times but also ensures the precision and quality of each piece produced.

Here, we take you through the basics of high speed stamping, shedding light on its processes, the uses it has across industries, and the balance of its advantages against its limitations.

What is High Speed Stamping?

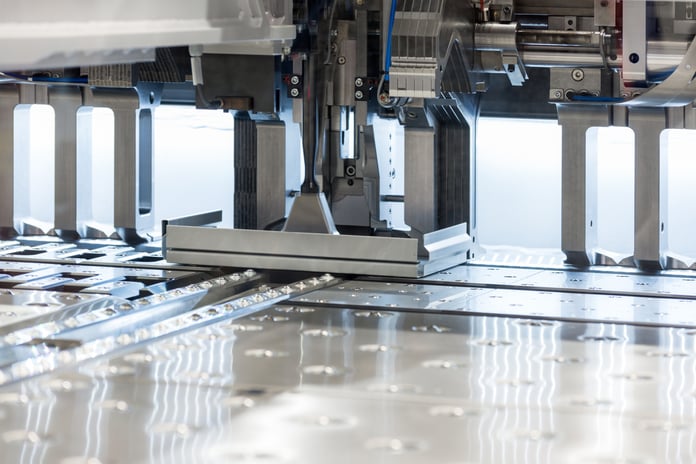

High speed stamping involves the cutting and shaping of primarily metal, but also plastic and paper coils or sheets, into specific forms at an exceptionally fast rate. This technique uses high speed stamping presses, often operating at speeds of hundreds or even thousands of strokes per minute. The process is ideal for producing precision parts in large volumes, making it a cornerstone in industries such as automotive, electronics, and medical devices.

The High Speed Stamping Process

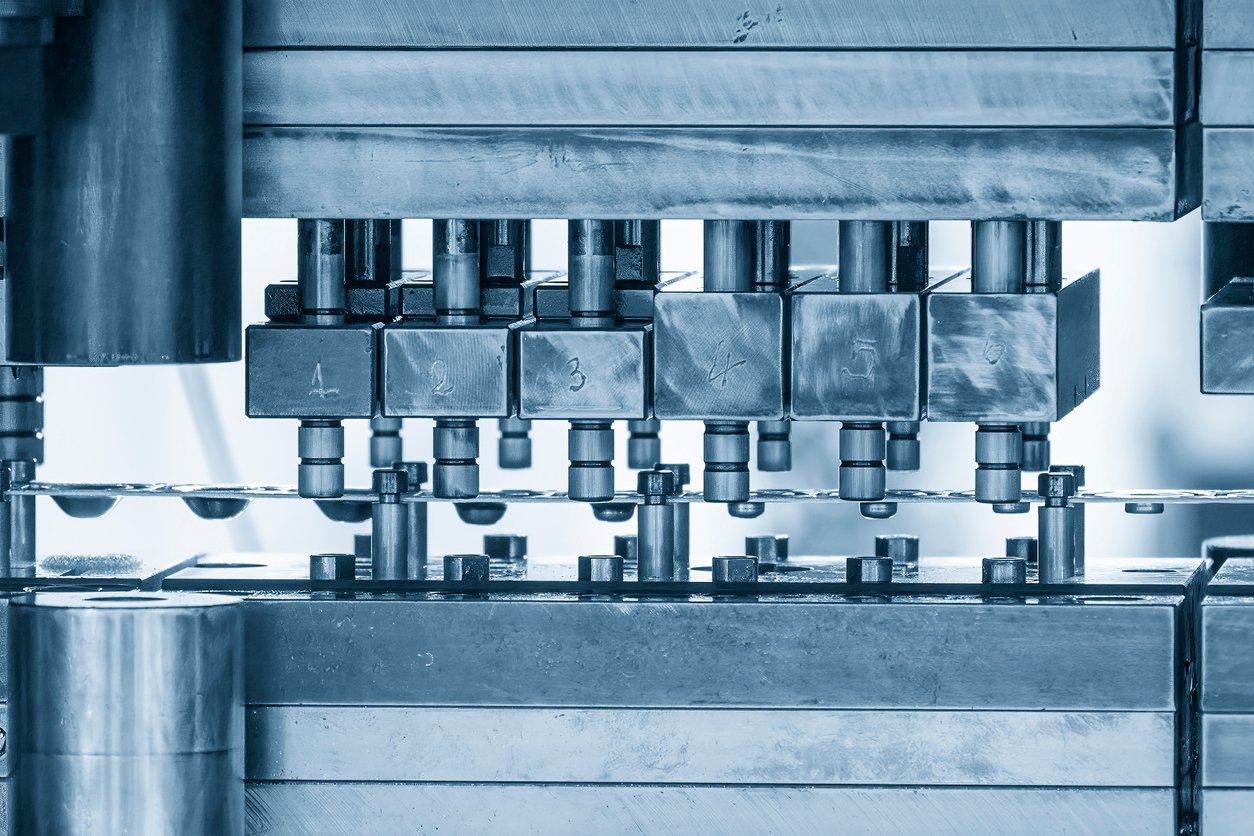

The core of the high speed stamping process involves a high speed stamping die – a specialized tool that shapes the metal. The metal sheet or coil is fed into the high speed stamping press, where the die stamps the metal into the desired shape at a rapid pace. This process can include punching, bending, embossing, or cutting, depending on the part design.

High speed precision stamping is a subset of this process that emphasizes extreme accuracy, catering to applications where even the slightest deviation can compromise the product’s functionality. High speed stamping machines are equipped with advanced controls and monitoring systems to ensure consistency and precision throughout the production run.

Uses of High Speed Stamping

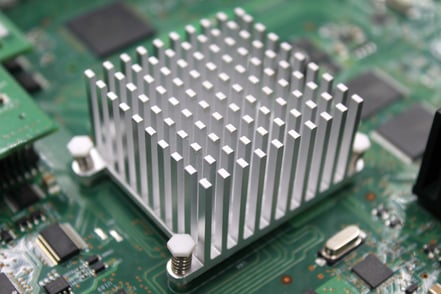

High speed stamping finds applications across a broad spectrum of industries. In the automotive sector, it's used to produce components like connectors, brackets, and various electrical parts. The electronics industry relies on high speed stamping for manufacturing connectors, heat sinks, and shields. Medical device manufacturers use this process for creating intricate components that require high precision and reliability.

Advantages of High Speed Stamping

High speed stamping comes with a plethora of advantages, including:

- Efficiency: One of the most significant advantages is the sheer speed at which parts can be produced, drastically reducing lead times.

- Precision: High speed stamping allows for the manufacturing of parts with tight tolerances, essential for many technical applications.

- Cost-Effectiveness: For large volume runs, high speed stamping can be more cost-effective than other manufacturing processes, due to lower labor costs and faster production rates.

- Versatility: This process can handle a wide range of materials and design complexities, making it suitable for various industries.

Disadvantages of High Speed Stamping

Every manufacturing process has its strengths and weaknesses. While high speed stamping is great for large-volume production of precise parts, there are several instances where another manufacturing process may be better. The setbacks of high speed stamping include:

- Initial Cost: The upfront cost for high speed stamping dies and machinery can be significant, although these costs are often offset by the efficiencies gained in large-volume production.

Pro Tip: Outsourcing high speed stamping to an experienced manufacturer can bypass the initial machinery cost.

- Design Limitations: While versatile, there are constraints on the complexity and size of parts that can be efficiently produced with high speed stamping. It’s important to consult with an expert to determine the best manufacturing method for your project.

- Material Limitations: Not all materials are suitable for high speed stamping, with the process primarily focused on metals.

High Speed Stamping: Efficient, Fast, & Versatile

High speed stamping’s ability to produce large volumes of parts quickly and accurately makes it an invaluable process for industries requiring high quality metal components. While there are considerations to weigh, such as initial investment and design limitations, the benefits of high speed stamping often outweigh these challenges.

Check out our blog for more information on metal stamping and other manufacturing processes.

You May Also Like

These Related Stories

The Metal Stamping Process from Start to Finish

Die Steel Material Choices That Shape Progressive Stamping

%201.png?width=146&height=103&name=Slice%203%20(72)%201.png)