Intro to Die Stamping Tools - How Do They Work?

Die stamping is a versatile and efficient manufacturing process used across various industries to shape metal, plastic, and other materials into precise parts and components. This technique is particularly favored for its ability to produce high volumes of identical parts with consistent quality.

In this blog, we'll explore the basics of die stamping, how it works, and its different types, focusing on progressive die stamping, among others.

What is Die Stamping?

Die stamping is a cold-forming process that uses a press and a set of dies (hardened steel or carbide tools) to cut, shape, or form sheet metal and other materials. The process is widely used in manufacturing for creating parts with specific shapes and sizes, ranging from simple flat washers to complex automotive components.

Metal stamping is hailed for its efficiency and ability to produce parts at high speeds, making it a cornerstone in the production of electronics, automotive components, consumer goods, and more.

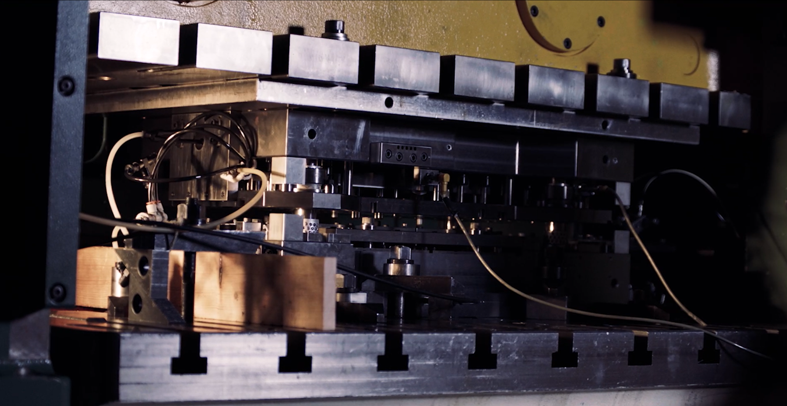

How Does Die Stamping Work?

The die stamping process involves several key steps:

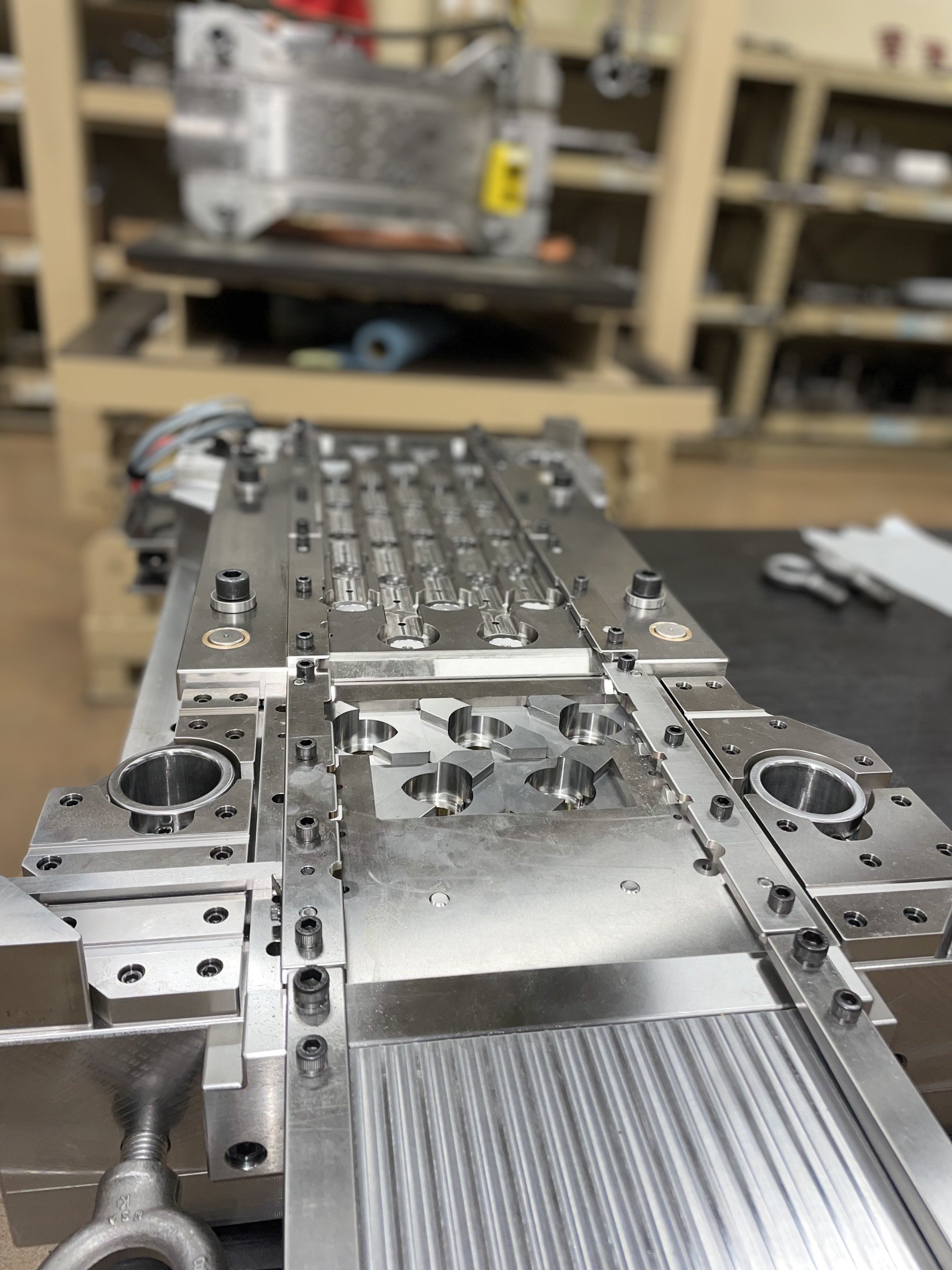

- Design and Creation of Dies: The first step is designing and creating the dies that will shape the material. These dies are made from high-strength materials, such as carbide or tool steel, to withstand the pressures of the stamping process.

- Material Feeding: Sheet metal or the material to be stamped is fed into the stamping press. This can be done manually or automatically, depending on the complexity and speed of the operation.

- Stamping: Once the material is in place, the stamping press uses force to press the die into the material, causing it to deform and take the shape of the die. This can include cutting, bending, embossing, or other shaping processes.

- Ejection: After the material has been shaped, it is ejected from the die, and the process repeats for the next piece.

Types of Die Stamping

Die stamping can be categorized into several types, each suited to different production needs:

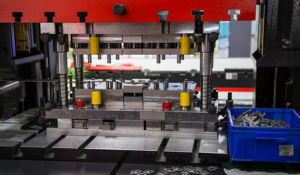

Progressive Die Stamping

This method involves using a series of dies in a row, each performing a different operation on the part as it moves through the process. It's highly efficient for producing large volumes of complex parts, as it combines multiple operations into a single pass.

High-Speed Stamping

Designed for operations requiring extremely fast production rates, high-speed stamping presses operate at higher cycles per minute. This is ideal for producing simpler parts at large volumes.

Sheet Metal Stamping

This type focuses on forming parts from sheet metal. It's widely used in automotive, aerospace, and appliance manufacturing.

Plastic Stamping

Similar to metal stamping, but specifically designed for plastic materials. This process can produce high-quality, detailed plastic parts for various applications.

Carbide Dies

These are used for high-volume or high-wear applications. Carbide is harder than steel, making these dies more durable and capable of maintaining precision over longer production runs.

Programmable Die Stamping

Within these tools, the cutting and forming operations can be activated and deactivated per stroke to allow different configurations within each part.

Advantages of Die Stamping

Die stamping offers several advantages, including:

- High Efficiency: Capable of producing large quantities of parts quickly.

- Cost-Effectiveness: Economical for high-volume production due to lower labor costs and minimal waste.

- Precision: Produces parts with tight tolerances and consistent quality.

- Versatility: Can be used with a wide range of materials and designs.

The Essential Role of Die Stamping

Die stamping is a critical process in the manufacturing industry, known for its efficiency, precision, and versatility. Whether it's progressive die stamping for complex parts, high-speed stamping for rapid production, or specialized stamping for materials like plastic, the process plays a pivotal role in producing the components that power our daily lives.

As technology advances, metal stamping companies continue to innovate, making die stamping an even more integral part of manufacturing across the globe.

Ready to learn more? Contact one of our experts today!

You May Also Like

These Related Stories

Progressive Die Stamping: An Overview

Progressive Die Stamping vs. Transfer Die Stamping: Comparison Guide

%201.png?width=146&height=103&name=Slice%203%20(72)%201.png)