ECM Vs. EDM Machining: What’s the Difference?

In the world of manufacturing, conventional machining continues to evolve, relying on more precise, efficient technologies. Two of these processes are electrochemical machining (ECM) and electrical discharge machining (EDM).

ECM and EDM are nontraditional subtractive manufacturing processes used to produce highly precise parts with intricate shapes from hard materials. In fact, EDM is considered a hybrid of ECM. Despite their similarities, it’s crucial to understand the differences between the processes.

In this blog, we’ll explore the key differences and similarities between ECM versus EDM to help you determine which process is best suited for your specific application.

A Breakdown of the Key Differences Between EDM Vs. ECM

Although EDM and ECM often achieve similar results, they use different sources of energy to operate – and that’s only one distinction. Let’s take a deeper dive into the differences between EDM vs. ECM, starting with their definitions.

The Basics of ECM vs. EDM

Electrochemical machining (ECM) uses electrolysis to remove material from a conductive workpiece. During the process, a workpiece is submerged into an electrolyte solution creating a chemical reaction. Material is then removed and the workpiece is formed into the desired shape and finished by a cathode. This process is non-contact, meaning the cathode never touches the workpiece, offering several advantages.

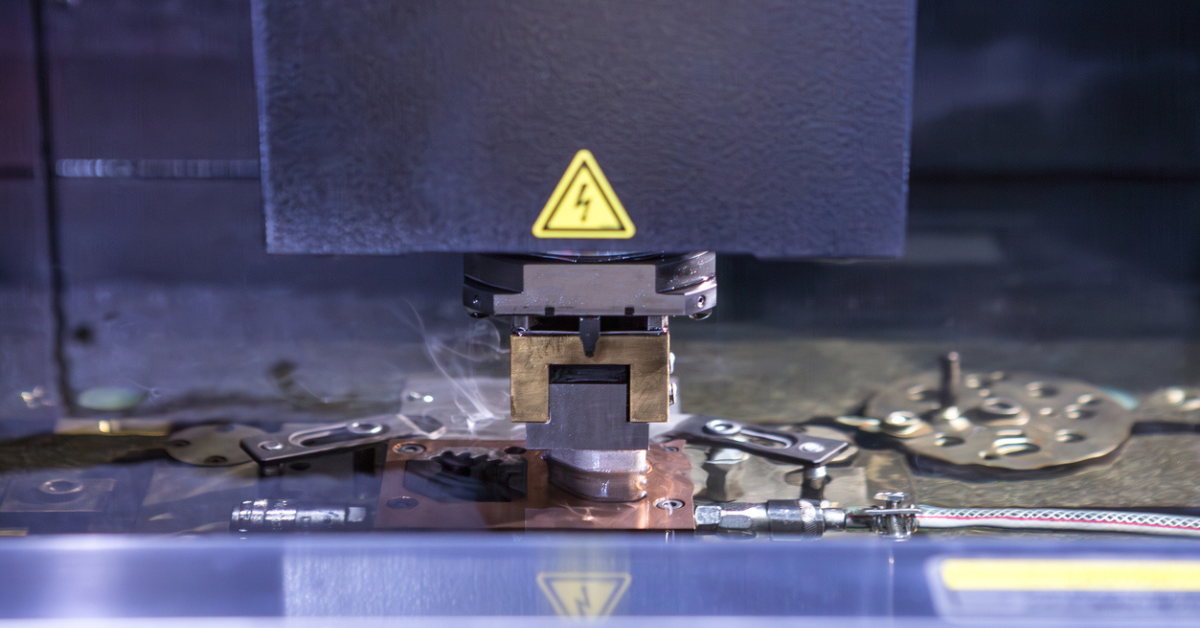

Electrical discharge machining (EDM), on the other hand, removes material from a workpiece through electrical discharges (sparks), causing erosion, rather than electrolysis. Like ECM, EDM is also non-contact, but it relies on a dielectric fluid to facilitate spark generation. The workpiece is submerged in this dielectric solution, which insulates and controls the electrical discharges..

There are two types of EDM: wire EDM, which uses a thin wire to cut intricate shapes, and Ram EDM, which uses a shaped electrode to erode material in a specific pattern.

Differences in Processes

While their definitions help one understand the core differences in each method, you can understand the distinctions even further by taking a look at the steps in each process.

In ECM, the general process looks like this:

- The tool is connected to the negative terminal (cathode), and the conductive workpiece is connected to the positive terminal (anode) of a power supply.

- Both the tool and the workpiece are submerged in an electrolyte solution to enable ionic conduction.

- A direct current is applied, initiating a chemical reaction that removes material from the workpiece (anode) at a controlled rate.

- The material is dissolved into the electrolyte solution, leaving behind the desired shape based on the tool geometry.

In EDM, the general steps look a bit different:

- A digital model of the desired part may be created using CAD software to design the electrode or wire path for cutting.

- The electrode (or wire in wire EDM) and machining parameters—such as voltage, current, and pulse duration—are configured based on the material properties and required precision.

- The electrode is placed close to the workpiece, leaving a small gap filled with a dielectric fluid that insulates and cools the process.

- A high voltage is applied, creating electrical discharges (sparks) that erode the material from the workpiece through intense heat.

- The dielectric fluid flushes away the eroded material and helps maintain stable sparking for consistent machining.

Differences in Fluids Used

Both EDM and ECM utilize a fluid-based solution that allows for the energy source to function. However, ECM uses an electrolyte solution (often a salt-based solution) that allows for the electrochemical reaction that breaks down metal and creates a piece’s final shape. EDM uses a deionized water or another dielectric fluid to allow for rapid electrical discharges, heat generation and ultimately vaporization that creates a piece’s final shape.

Differences in Cost

Electrochemical machining and electrical discharge machining differ in their cost as well. ECM has a relatively higher initial cost that includes equipment setup, supplies, solutions and machine maintenance. However, the return on investment and efficiency could justify the higher upfront cost. Since EDM is common and machinery is more widely available, upfront costs can be lower than ECM. However, long-term maintenance and production costs can be higher.

One way to ensure your investment is worthwhile is by outsourcing your machining. Outsourcing to a reputable company can be a cost-effective way to reduce startup expenses and eliminate the need for extensive in-house training. Plus, by partnering with experts who bring efficiency, precision, and industry experience to the table, you can focus on your core operations while ensuring high-quality results.

An Overview of the Key Differences Between EDM and ECM

To simplify ECM vs. EDM, here’s an overview of their key differences that will help you decide which best applies to your project.

|

|

|

|

|

Definition |

A machining process where a machine uses electrolysis to break down the material on a conductive workpiece |

A machining process that uses an electrical discharge (spark) to remove material from a workpiece through erosion |

|

Power Source |

Electrochemistry or electrolysis |

Electrical discharges or spark discharges |

|

Fluids Used |

Electrolyte solution (salt-based solution) |

Dielectric solution (deionized water or kerosene) |

|

Types |

Grinding, polishing, electroplating, etching |

Wire EDM, Ram EDM |

|

Cost |

Higher upfront cost |

Lower upfront cost |

Key Similarities Between ECM and EDM

Now that we know what makes each process unique, we can take a look at what these two popular machining methods have in common:

|

|

|

|

Non-contact processes |

Neither tool used in ECM or EDM makes contact with the material – there is a gap between the workpiece and the tool while removing material. |

|

Compatibility with materials of all hardnesses |

Each method works on most metals and materials, regardless of their hardness, or lack thereof. |

|

Need for conductive materials |

Materials must be electrically conductive to some degree for either power supply to operate. |

|

Overlap in applications of ECM and EDM |

The precision and efficiency of ECM and EDM make them both go-to manufacturing methods for high-standard sectors like the aerospace, medical and automotive industries. |

Read more about the applications of ECM in aerospace here.

Choosing Between ECM and EDM For Your Next Project

Choosing the right machining method for your project can make all the difference in achieving precision, efficiency, and cost-effectiveness. ECM and EDM offer unique advantages and cater to specific applications, but understanding their differences – like power sources, fluids used, and costs – can help you make an informed decision.

By outsourcing your machining needs, you can eliminate upfront costs and learning curves associated with in-house production. If you’re unsure which machining method is best for your project, don’t hesitate to reach out. Whether you’re exploring ECM, EDM, or considering outsourcing for streamlined operations, we’re ready to help bring your vision to life.

You May Also Like

These Related Stories

EDM Metals: Choosing Materials for Electrical Discharge Machining

Using the Electrochemical Machining Process for the Aerospace Industry

%201.png?width=146&height=103&name=Slice%203%20(72)%201.png)