4 Innovative Cost Reduction Ideas in Manufacturing Metal Parts

Manufacturing Cost Pressures: Why Old Cost-Cutting Fails

In metal parts manufacturing, the pressure to remain competitive without compromising quality is a constant challenge. Traditional cost-cutting measures, such as using cheaper materials or reducing quality checks, often backfire by increasing waste, rework, and downtime.

The true opportunity for meaningful cost reduction lies not in cutting corners, but in engineering smarter. By leveraging proactive design and process innovation, manufacturers can embed efficiency directly into how parts are made.

This article outlines four proven cost reduction ideas that enhance efficiency and quality in metal parts manufacturing: Design for Manufacturability (DFM), lean process optimization, advanced manufacturing technologies, and AI-powered digitization. Together, we’ll dive into how these strategies reduce waste, shorten cycle times, and lower costs to improve part quality and market competitiveness.

1. Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is the practice of designing components to be as easy and efficient to produce as possible. This approach prioritizes ease of production, assembly, testing, and servicing from the earliest design stages.

Since design choices lock in the majority of a part's cost long before production begins, DFM is a critical first step in cost control. Misaligned geometry, unnecessarily tight tolerances, or poor material choices inevitably lead to costly rework, scrap, or tooling fixes down the line.

When engineers apply DFM principles, they bridge the gap between design intent and shop-floor reality, preventing expensive tooling rework and production delays. Core tactics for lowering costs through DFM include:

- Simplify geometry: Eliminate complex features like compound curves or undercuts that require specialty tooling

- Tier tolerances: Reserve ultra-tight tolerance callouts only for surfaces that are critical to the part's function

- Material–tool match: Select material thickness and alloy with formability and tool life as primary considerations

- Simulate upfront: Utilize digital modeling tools to simulate springback, thinning, and bending instead of relying on physical trial-and-error

Digital simulation software like ANSYS or SolidWorks Simulation allows engineers to model material behavior before physical tooling is made. This predictive analysis identifies and resolves design-induced defects early, reducing the need for multiple tooling trials, minimizing setup waste, and cutting troubleshooting time.

2. Lean Process Optimization

With a design optimized for manufacturing, the shop floor becomes the next area for significant cost reduction. Lean manufacturing methods are proven strategies for shrinking unit costs by systematically targeting and eliminating waste.

SMED for Faster Changeovers

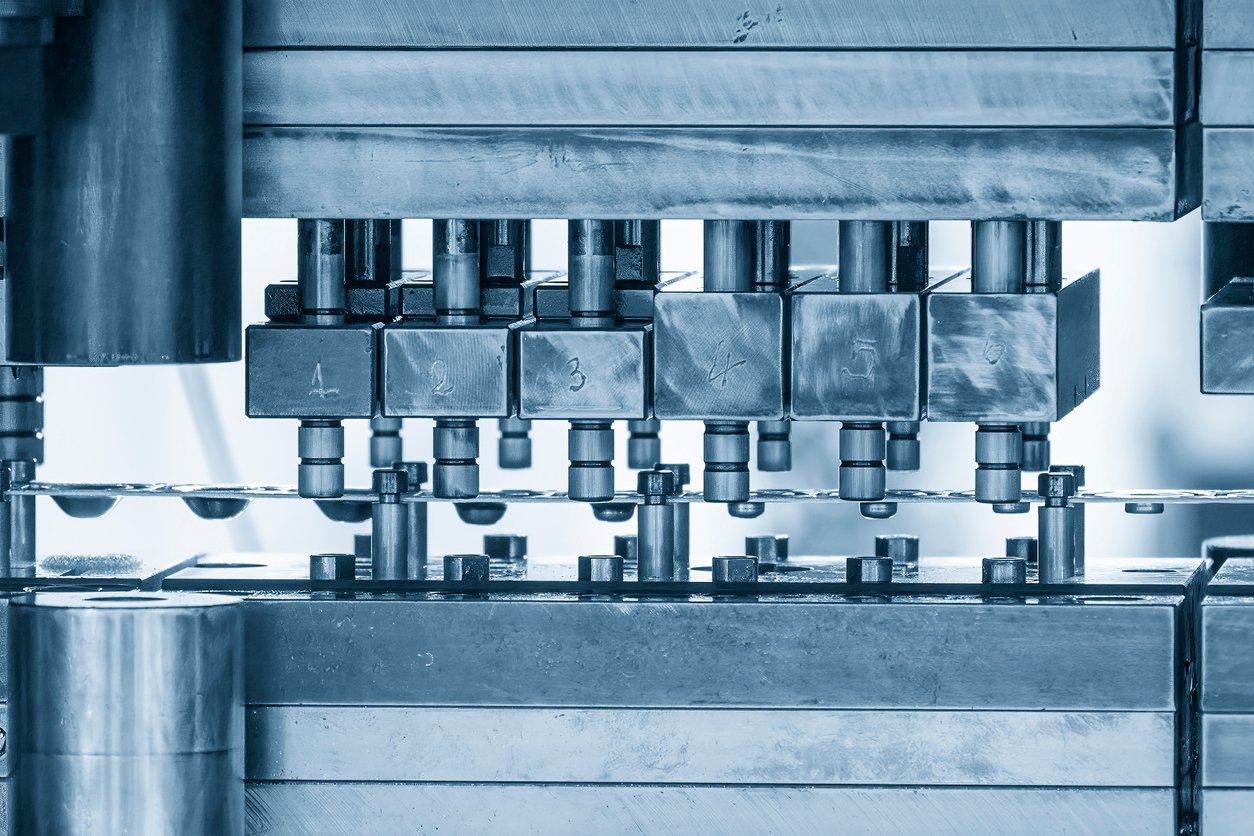

Single-Minute Exchange of Dies (SMED) is a methodology that uses modular tooling and external preparation to cut machine changeover times to under 10 minutes. Reducing setup time with SMED not only accelerates production but also enhances operational flexibility, allowing manufacturers to manage a higher mix of SKUs without carrying excess inventory.

Tooling as a Cost Multiplier

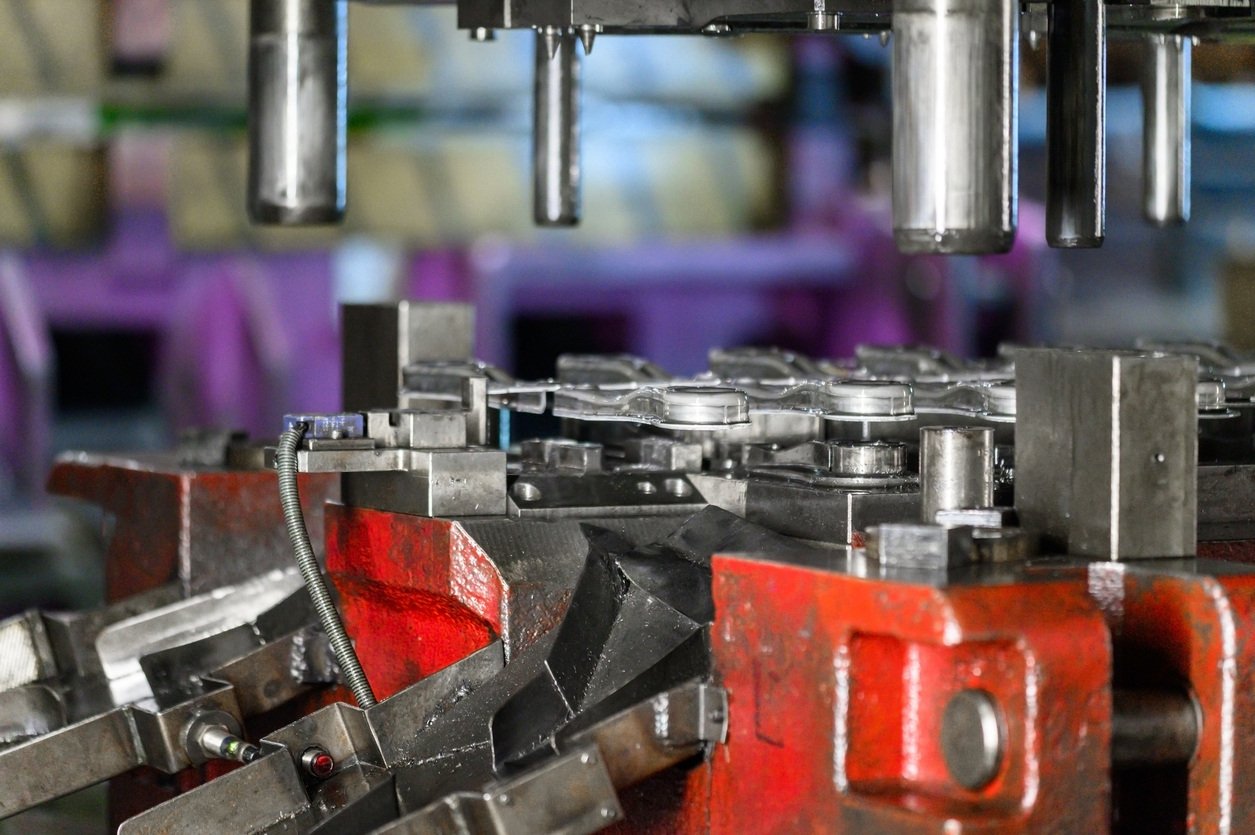

In stamping operations, extending tool life and preventing unplanned downtime are critical but often overlooked cost levers. The use of hardened tool steels or carbide inserts can significantly reduce wear when working with abrasive materials. Furthermore, optimized lubrication systems lower friction and heat, preserving tool integrity.

Predictive maintenance technologies, from vibration analysis to thermal imaging, enable teams to anticipate tool failure before it halts production. For high-speed progressive die operations, even modest improvements in tool uptime compound into major annual savings.

3. Advanced Manufacturing Technologies

As manufacturers face global labor shortages, rising energy costs, and increasing product complexity, automation and precision processes have become essential for cost reduction. These technologies stabilize output quality and enable scalability without a proportional increase in labor or capital investment.

Automation

Automated production lines and in-die processes reduce direct labor while simultaneously improving consistency and throughput. By integrating automated part handling, in-press sensors, and other in-die features, multiple steps can be merged into a single, seamless operation.

Research indicates that automation often lowers variable costs by 20–40% through scrap reduction, improved yield, and more efficient resource utilization.

ECM for Precision Finishing

Electrochemical Machining (ECM) is a non-contact process that delivers exceptionally high precision on intricate geometries without introducing mechanical or thermal stress. The process removes material atom by atom via electrolysis, creating mirror finishes and eliminating the need for secondary deburring or polishing operations.

For high-value components in the medical, aerospace, and energy sectors, ECM eliminates multiple manual finishing steps, extends tool life, and reduces quality rejects.

Additive Manufacturing for Rapid Prototyping

While not yet cost-effective for high-volume production of stamped parts, additive manufacturing (3D printing) dramatically reduces upfront R&D costs. Technologies like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) allow for the rapid prototyping of dies and fixtures, enabling manufacturers to test designs digitally before committing to expensive hard tooling.

Predictive Metrology

High-speed, multi-sensor metrology systems accelerate part validation and prevent costly rework. For example, JV Manufacturing's deployment of the OGP Fusion 400 reduced typical inspection time from 90 seconds to approximately 10 seconds per part. This ten-fold improvement enables faster feedback loops and minimizes production downtime.

Manufacturers can achieve compounding efficiency through the integration of automation, ECM precision, additive prototyping, and metrology-driven intelligence. This synergistic approach leads to measurable improvements in quality and throughput across the entire production ecosystem. The results are lower per-part costs, improved uptime, and shorter lead times.

This integrated methodology sets a new standard for competitive metal part production. The next advancement involves connecting these systems through digital intelligence, where AI and real-time analytics can further amplify these benefits.

4. AI and Digital Transformation

For efficiency gains to continue, they must be driven by intelligent, data-driven decisions. AI, data analytics, and real-time control systems are enabling a new level of responsiveness in programming, scheduling, and quality control.

AI-powered tools can transform reactive production into proactive management:

- AI-assisted CNC programming: Automatically generates optimal toolpaths and setup sequences

- Dynamic scheduling engines: Reallocate jobs in real-time to protect Overall Equipment Effectiveness (OEE)

- Predictive quality control: Uses analytics to detect process drift and defect correlations before scrap is produced

Modernizing legacy equipment with PLC-based control systems and integrating AI-enabled vision inspection tools bridges the gap to a smart factory environment. When every press, tool, and inspection system communicates in real-time, downtime and defect rates fall while operational agility rises.

Turning Efficiency Into Advantage

The true power of cost reduction is realized when DFM, lean operations, advanced technologies, and AI-driven systems are combined. When applied together, these strategies not only reduce per-unit cost but also enhance consistency, shorten lead times, and raise the competitive bar for quality.

In an industry where margins are tight and complexity is growing, manufacturers who design smarter, build leaner, and learn faster will ultimately win.

Explore how tooling & ECM solutions can be part of your next optimization step and request a quote to diagnose your highest-leverage cost levers.

You May Also Like

These Related Stories

How Much Does CNC Part Machining Cost?

Metal Stamping Applications for 3 Key Industries

%201.png?width=146&height=103&name=Slice%203%20(72)%201.png)