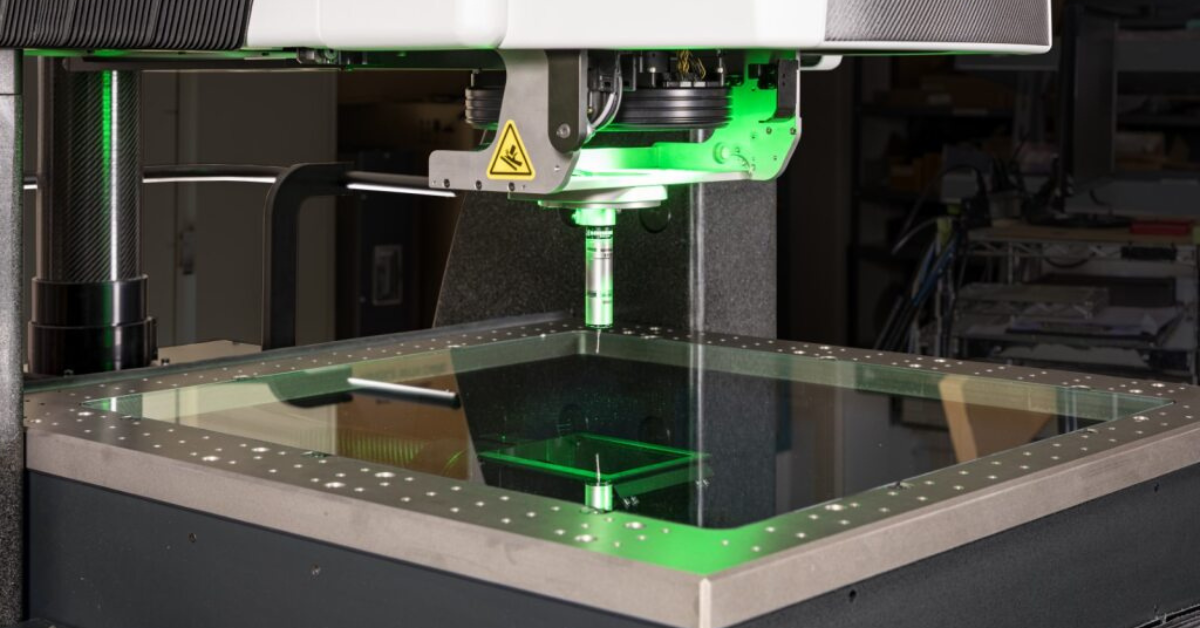

We’ve expanded our inspection capabilities with the OGP Fusion 400, a multi-sensor metrology platform that unites video (optical), laser, and tactile probing in one system. Its CNC-driven, unattended routines and 400 × 300 × 250 mm measurement envelope allow complex parts to be checked consistently and repeatably, achieving micron-level accuracy (down to ±1.5 µm, configuration-dependent).

In day-to-day use, the Fusion 400 has reduced a typical inspection from ~90 seconds to about 10 seconds, boosting throughput to hundreds of parts per week while strengthening first-article and in-process verification. The net result: faster feedback to the floor, tighter traceability, and fewer surprises downstream.