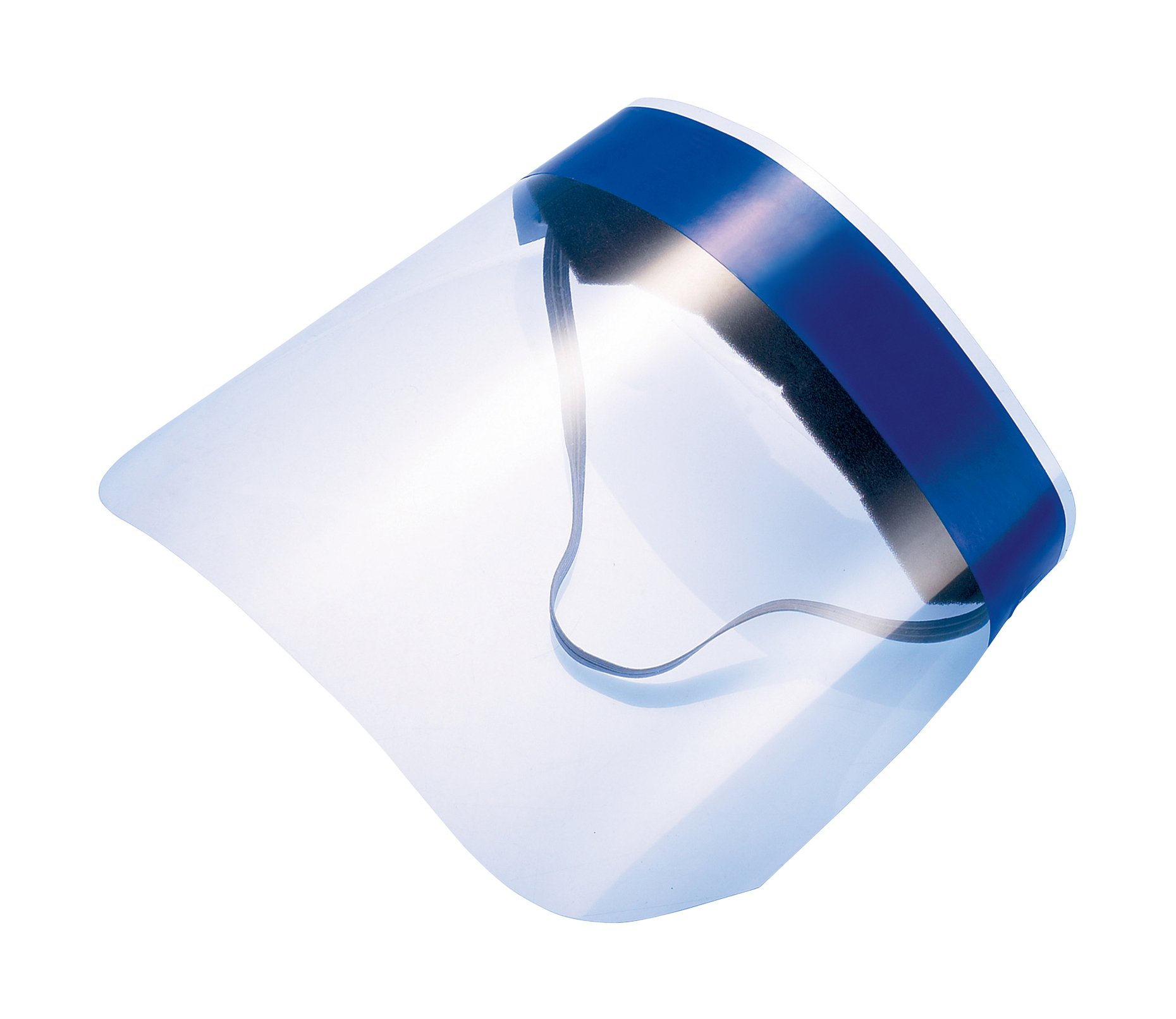

Rapid Production of Face Shields for Pandemic Response (2020)

Industry

Manufacturing

Challenge

The COVID-19 pandemic created an urgent need for face shields in healthcare. Meeting the high demand was tough, with tight deadlines, supply chain issues, and not enough workers, all without an existing product line to work from.

Results

JV Manufacturing produced 13 million face shields in 4 months with near-zero defects, saving lives and boosting the local economy by employing 10 displaced workers and collaborating with regional suppliers.

Solution

Design & Engineering, Tooling & Setup, Supply Chain & Materials, Workforce & Production Strategy

I wanted to thank you and the whole JV team for the partnership to complete the Face Shield production. This project was outside our normal processes and brought many challenges for both of our companies. It was only with the dedicated assistance of Tom and the entire JV team that we were able to overcome so many obstacles to complete this project. Please pass my thanks to the entire group.

- Kline C.

Executive Summary

In March 2020, as the COVID-19 pandemic triggered an unprecedented crisis in personal protective equipment (PPE), JV Manufacturing swiftly adapted, transitioning from precision metal stamping to medical device production within a mere 10 days.

Despite lacking prior experience in PPE, the company leveraged its engineering prowess and strong community partnerships to produce and deliver over 13 million face shields to healthcare workers facing critical shortages.

This rapid and effective response highlights the agility of American manufacturing in addressing national emergencies and supporting local communities.

This achievement was made possible through innovative tooling, the establishment of domestic supply chains, and the unified efforts of its workforce.

The Challenge

The pandemic's arrival brought American healthcare to a breaking point. Hospitals reported days of PPE supplies remaining. International supply chains had collapsed. Healthcare workers faced impossible choices between personal safety and patient care. For JV Manufacturing, three critical challenges converged:

- Zero to Production Pressure: No existing medical product line, tooling, or certifications—yet healthcare partners needed millions of shields immediately

- Supply Chain Chaos: Global material shortages and shipping delays threatened any production timeline

- Operational Constraints: COVID-19 restrictions limited workforce availability while demand required 24/7 production capacity

The margin for error was zero. Every day of delay meant healthcare workers remained unprotected.

The Solution

In the face of extreme supply chain challenges and urgent needs from the front lines, JV Manufacturing undertook a coordinated, comprehensive response.

Our teams worked side by side to accelerate engineering innovation, adapt facilities and tooling, strengthen our supply chain, and put a thoughtful workforce strategy into place.

Each element—engineering, tooling, supply chain, and workforce—played a critical role in delivering rapid, reliable solutions to our healthcare partners.

Design & Engineering

To kick off our efforts, the engineering team quickly analyzed and improved face shield samples provided by healthcare partners.

By leveraging advanced die design and utilizing in-house 3D printing for rapid prototyping, we refined shields for both maximum protection and efficient large-scale production. Final designs were delivered within just 72 hours.

Key achievements:

- Reduced assembly components by 40% compared to original designs

- Improved material use to cut waste by 30%

- Developed universal sizing to meet the diverse needs of healthcare workers

- Rapidly sourced and installed specialized equipment to support increased production capacity

Building on these engineering advancements, we seamlessly transitioned to the next crucial phase: scaling up our operational capacity to meet escalating demand.

Tooling & Setup

With engineering foundations set, our tooling experts immediately began building custom die sets—accomplishing in days what is often a weeks-long process—using available stock.

By swiftly reconfiguring stamping and assembly areas, we converted precision metalworking lines into dedicated medical device production spaces.

Highlights include:

- Created adaptable tooling to handle a variety of materials and shield types

- Launched three complete production lines within 30 days

- Installed quick-change systems for rapid switching between shield styles

- Met existing customer needs while simultaneously scaling up PPE output

As production capabilities expanded, the focus naturally shifted to ensuring a steady, reliable flow of materials needed to sustain output at scale.

Supply Chain & Materials

Recognizing that global supply chains couldn’t keep up

with urgent demand, we proactively built a domestic network by teaming with local and regional suppliers, including ProEx Extrusion for plastics and sourced packaging from nearby businesses affected by closures.

This approach resulted in:

- 75% faster material lead times

- Tangible support for local businesses in need

- Increased supply chain resilience during global disruption

- Streamlined logistics for faster, more dependable deliveries

With robust production and supply processes in place, the logical next step was to optimize our internal operations and invest in the well-being of our people.

Workforce & Production Strategy

To ensure both operational continuity and community support, we adopted a forward-thinking workforce plan. Rotating crews were arranged for safety; we welcomed displaced workers—including family members—into our workforce and invested in cross-training across job roles.

Notable advances:

- Integrated semi-automated systems for optimal speed and quality

- Simplified assembly steps to speed up onboarding and training

- Embedded real-time quality assurance throughout the production line

- Maintained safe, continuous 24/7 operations through strategic shift management

By working together and remaining flexible, our team sustained high productivity, ensured consistent quality, and looked out for the well-being of our employees and community—even in the most challenging circumstances.

The Results

JV Manufacturing produced over 13 million face shields in four months with near-zero defects, shipping the first 15,000 in seven days and reaching full production in under ten. They also created jobs, supported local suppliers, and optimized resources, receiving formal recognition for preventing PPE shortages and protecting healthcare workers.

JV Manufacturing rapidly pivoted from metal stamping to producing 13 million face shields in 10 days, demonstrating American manufacturing's adaptability and commitment during a crisis.

This feat protected healthcare workers and showcased how engineering, leadership, and partnership can overcome "impossible" challenges, turning manufacturing into a life-saving force. The company maintains these agile systems for future emergencies.

%201.png?width=146&height=103&name=Slice%203%20(72)%201.png)